Laser Cladding

•Improves the wear resistance, corrosion resistance, and overall durability of components.

•Can apply to a variety of materials, including metals and alloys.

Advantages

•Uses a laser to melt and deposit material onto the substrate, creating a metallurgical bond.

•Has precise control over heat input, resulting in minimal thermal distortion.

•Creates a metallurgical bond, which is typically stronger.

•Produces coatings with low porosity and high density.

•Requires precise laser equipment and control systems.

•Laser cladding often results in fine martensite structures and intermetallic phases, contributing to high hardness values.

Coating Material

•Fe-Based Alloys: Laser cladding can produce coatings with hardness values ranging from 580 to 630 HV.

•Ni-Based Alloys: These coatings typically exhibit high hardness and excellent wear resistance.

•Ceramics (e.g., SiC): Laser cladding of SiC/ZL101 composite coatings can significantly enhance hardness and wear resistance.

Laser Cleaning

•Efficiently remove contaminants, rust, and coatings from mechanical components without damaging the base material. This precision process enhances surface preparation for repairs, extends component lifespan, and ensures optimal performance in critical industrial applications.

Key Features:

•Non-abrasive & precise – Protects part integrity.

•Eco-friendly – Eliminates chemical waste and media blasting residues.

•Restores performance – Ideal for overhauling high-value components.

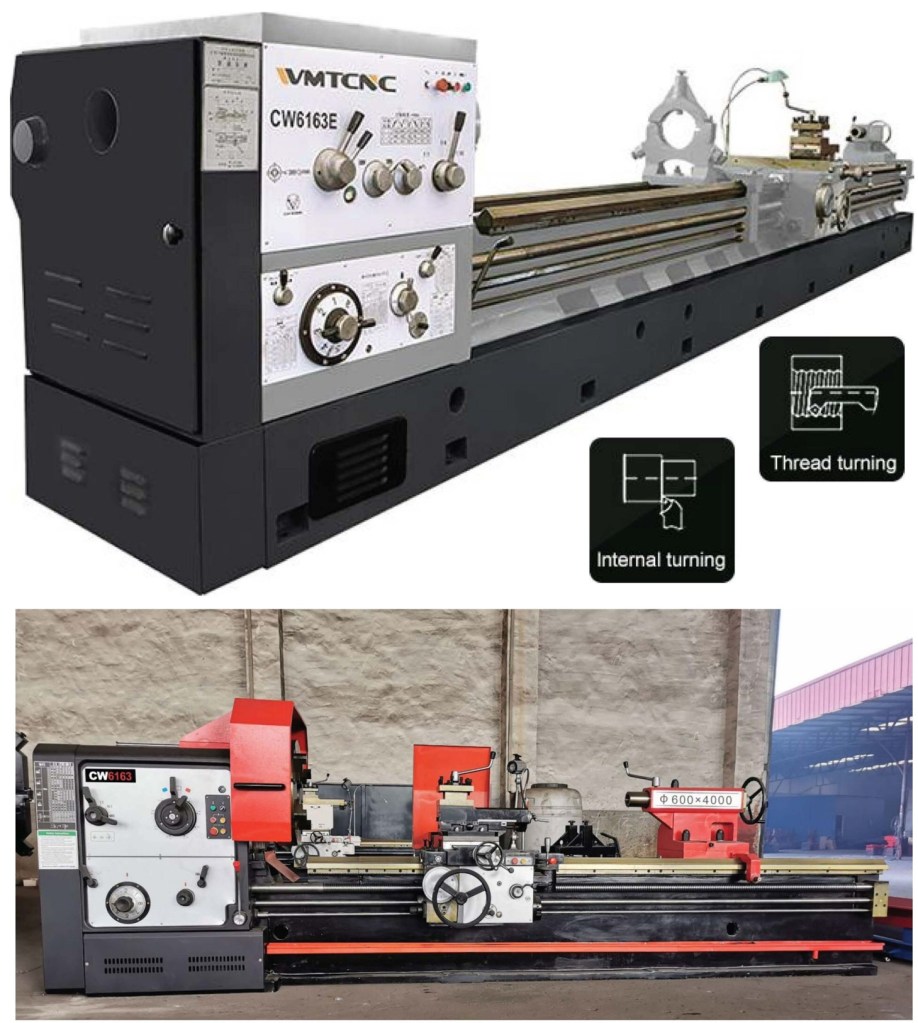

Lathe Machine

•Precision lathe machining restores functionality with accuracy and reliability. From worn shafts to complex fittings, it ensure high-tolerance refurbishment to extend equipment lifespan and performance.

Key Features:

•Precision & Accuracy

•Versatility – Covers shafts, fittings, and other components.

Vertical Lathe machine

•Precision lathe machining restores functionality with accuracy and reliability. From worn shafts to complex fittings, it ensure high-tolerance refurbishment to extend equipment lifespan and performance.

Key Features:

•Precision & Accuracy

•Versatility – Covers shafts, fittings, and other components.

Benchtop Precision Universal Cylindrical Grinder

•Delivers high-accuracy machining for the overhaul and repair of mechanical components, ensuring tight tolerances and superior surface finishes. Compact yet powerful, it’s ideal for restoring shafts, bearings, and other cylindrical parts to like-new condition with efficiency and reliability.

Key Features:

•Precision grinding for critical tolerances

•Versatile – handles shafts, bearings, and cylindrical parts

•Reliable performance for repair and overhaul operations